Work day

Company Meeting: Fun fact of the day-Jerry is also a Pilot!

Jerry leads meeting, Melody got snacks and bananas. The bananas are symbolic of an employee named Bob that passed away who ate a banana every day. Jerry gave the financial update and went through each of the 17 or so projects that are beginning, ongoing or on their way out. Some customers are coming today and Wednesday to see the progress on their product. One account they lost to Japan who could complete project for less money. A big 1Million dollar job is about to go through, everyone is excited about it. Need to meet Travis. In October, Mertek Solutions has a Manufacturing Day to promote manufacturing to the community, especially school aged kids. Jerry mentions that some rearranging, organizing and selling on ebay has been taking place and thanks his employees for his patience. He has several Durham Bull Baseball tickets if anyone wants them. He is hosting a Conceal and Carry weapon license class asap. 11 Bar East Ranch you can take your kids for free when you mention you are an employee, great place to take the family for free. There is a boat for sale. Melody mentions if you get an email or bill from BCBS, just ignore it.

Melody shows Henrietta into our office space where we can get caught up on some assignments and allow them to work awhile without us being in the hair.

My reflections so far is that Mertek solutions is VERY family friendly, very laid back and organized at the same time. I watch Cake Boss and a lot of what goes on here reminds me of that show 🙂

After lunch Day 2

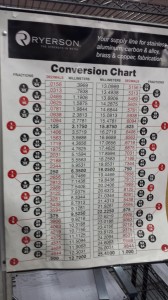

Met with Ronnie, a tool/mold maker. Kind of like a machinist, but in 2D. Hot roll is a cheaper material. He uses an old metal lathe. Add water/oil soluble coolant because the hot metal will destroy the bit. To cut aluminum use WD40. Watching this process it reminded me of sewing. Uses unit conversions a lot! There are newer digital read out machines and then the old manual machines. To “tap your hole” you must slow your speed. Saw the grinder machine which cuts hardened metal.

David More about WELDING! I love this welding-LOTS of chemistry and I know this will excite my students!! I may even get to weld soon!! The weld gives off UV light, so you have to protect your eyes with Dark tinted welding lens. Room has to be well ventilated as I soon discovered because of the smell form the gases and metal melting. Today David showed me a red tip: Tungsten mixed with Thorium for use on Stainless Steel. A green tip is pure Tungsten for use on aluminum. Aluminum uses Alternating current and Stainless Steel uses Direct Current. First he stitches the metal then he goes back and weaves the metal like a dirt dabber mud wasp or icing on a cake. There are many types of weaves. You use whichever the metal requires. C, J, hook, etc… He had to increase the Amps, more power he said and it would go faster. There is a transformer in his welding room and he uses 220 V from the wall outlet. Used alcohol to clean off contaminates on the metal, such as rust, grease, paint or oil. Oxygen and atmosphere is a welder’s enemy and second enemy is gravity. The picture of the bent metal tubes is because he was telling me how in math class we teach hypotenuse and parallel lines, but that is a real world example of it and how using pi and angles he could weld those together. He took a bio-manufacturing class but most of his knowledge comes from the MSDS (Material Safety Data Sheets) that come with the metal, he reads it and absorbs the knowledge! That makes a science teacher so happy! Each piece of metal also has a traceable number on it which includes: company, grade of metal, sometimes the shift and heat number.

Met with Melody, the office manager and by manager I mean this ship would sink without her! She uses math all day everyday! She showed us the Mertek Organizational Chart and I checked off whom I had met and who I still need to meet, some are on vacation and some are just extremely busy with project deadlines right now. She designed a general ledger in software called Quickbooks. She sets up the job number, etc. The ledger allows the customer and vendor info to be placed in the same software. The customer pays 30% at the time of purchasing, 30% when the design is finished, 30% when the customer comes to see the finished product prior to shipping and then the last 10% at the end after the manual is written, everything is good to go and when the product is at the company.