I heard someone recently say, “if you’re the smartest person in the room, it might be time to change what you are doing.” Unfortunately, I have interacted with so many people lately that I cannot recall who said it to me, but it resonated with me. Working at Caterpillar has been one of the most rigorous and intellectually challenging experiences in my life. This is a compliment to the knowledge of employees I have been surrounded by, the complexity of the information being processed, and the rigor involved in producing a quality product. When I’m at CAT I have to remind myself that I too am a bright and capable person just not in many of these areas. Since arriving at CAT most conversations I am involved in, I have been totally unequipped to productively contribute in. This is based on my exposure and my experience prior to starting with CAT.

I’m not saying all this to get affirmation or to hear from any of my readers comments like, “No Annah, you are so smart.” Or “No Annah, you are so bright.” That is not why this is included here, I have chosen to include this because I have been truly grateful and humbled to encounter so many patient and articulate employees at CAT. Countless people have donated their time to let me into their lives and their working environment. Explaining what they do and how it intricately intertwines with the work that the other employees do within Building Construction Products (BCP) Division. All of them between Clayton, Sanford, and Cary.

It’s humbling being in a room of bright, passionate, and intelligent people. To be honest throughout this process it has even been intimidating to me. And while I know that I am missing a great deal of the information being, I’ll say “thrown” at me there is just as much steadily starting to absorb with each passing day and with that ideas are starting to generate in my mind for my fellowship.

To revisit the quote I began with, I’m not sure that I’ll ever think of myself as the smartest person in a room, even when I am surrounded by 10 year olds, there is a good chance that I am not the smartest. I can say right now it’s nice to know at CAT I am definitely not. I enjoy being pushed and challenged to think differently and to push my current understandings and explore new territory. And in this way, I never have to worry about being the smartest in the room. All I need to continue to do is to keep a growth mindset, continue to communicate effectively, and be willing to admit, “I don’t know.”

I imagine this feeling of being intimidated, less than, or unequipped is shared amongst the students whom I teach or for a person beginning in a new position in any company. I think it is easy to forget the time before the things you know now and all the steps it took to arrive “here”. Things take time. So don’t worry about being the smartest and if you think you are, then find a different room because we all have a lot to learn and a long way to go!

Here are a few of the ways I grew in week 2 and I’ll dare to say became I little bit more knowledgable about…

Safety HOP

I went on a second and third safety hop this week with Emma and David. I really enjoy this process and talking about ways to improve safety for employees. A quick side tangent… Last week I spent some time in the torque lab with Jason and got to feel the torque of some of the tools. It would be SO easy to injure yourself using this equipment. Jason, showed me the proper posture to reduce strain on my shoulders, how to grip it, and hold it to minimize risk for injury. Since there is change over on assembly and people rotate their positions frequently it makes training and Safety HOPS even more essential! It presents an opportunity to have an employees process analyzed and reviewed to ensure best practice is being utilized when assembling the part. In typical Caterpillar fashion I wanted to begin this blog post with talking about spotlights on safety.

Quality Assurance- Randy Hayward’s Team

I got to meet many wonderful people in Quality last week. I enjoyed learning about the process of investigation and determining where and how each issue is happening. The more important message emphasized was understanding how to determine the root cause to actively take steps to ensure that quality is a priority. There are many quality checks taking place during engineering, assembly, prior to machines leaving the plant, and even when they are in the field. Quality has many layers. Part of Caterpillars core values is Quality. It is essential to the company to ensure that costumers are getting a high quality product and that it is upholding the CAT brand throughout it’s lifespan.

Acronyms (TMA- TOO MANY ACRONYMS)

“Hey Annah, do you want to join the meeting where we will be discussing NPI and CN’s. We will be looking specifically at risks in PPM for quality. Also we will discuss DPU and MIS and QCL. Got that?”

Alright… this isn’t totally accurate in that maybe I exaggerated the frequency of use of acronyms, but this is most certainly how many conversations feel to my untrained ears. I have spent a great deal of time trying to catch up in the conversations I have participated in. By the time I process and remember what the acronym means I have missed several more details and sometimes questions I am being directly asked. I know this might sound like I am complaining, but I am not. I am saying this because it has reminded me of a few important lessons.

- Pause to check if the people you are conversing with are understanding what you are saying. Use verbal and non-verbal clues to ensure their understanding of the message.

- Do not use an acronym or abbreviation that you cannot explain (Thanks Annette for this advice)

- Don’t take what you know now for granted, be patient and kind in teaching those around you what you know.

- This is how students/supplies/customers/new employees probably feel about 50% of the time. The first exposure to new vocabulary or content can be challenging. It takes multiple exposures to vocabulary for comfort to grow. This is why it is also important to connect vocabulary or acronyms with application/experience. I have been more likely to retain an acronym when I have directly interacted with it. For example; the acronym (CN), Change Notice, which happens in engineering when reworking a design and the protocol for notifying the proper channels about the change (suppliers, assembly, quality, etc). I am comfortable with this acronym because of my experiences learning about it. When it is used now in conversations I am right their with them, but prior to that I was not.

In corporate settings acronyms come up in almost every conversation. It is what I like to think of as corporate jargon. Every company will have their own, this is even true in teaching. When you first start at a company or even when you are well established within a company you have to be willing to ask questions or you might miss something. Acronyms is one example of things you cannot be too shy to ask about. People who have been in this field, at CAT for a long period of time take for granted this knowledge. It is essential when you do not understand that you ask. It helps provide the further information that you need. If you do not ask what these acronyms mean there is a good chance you are missing the purpose of the conversation or how this component of what CAT does connects to everything else. There is also a good chance that someone around you is also just as confused as you are! So ask!

Do hard things

One thing that has been iterated and reiterated to me over and over again since coming to CAT is that not everything is going to be easy. CAT values personal growth and encourages ownership. Employees are encouraged to do hard things. Not to shy away from taking APPROPRIATE risks in the working environment. The key thing here is that CAT doesn’t want employees taking off the cuff risks because that could interfere with safety, quality, etc. But what they do want to see happening is people stepping into new and challenging roles. Kenan Fellows has presented me with the opportunity to do something that is hard for me personally. I find the interactions easy, but the content challenging. In one of my first blog posts I talked about taking small steps outside of your comfort zone and slowly your zone of comfort expands. Everyday mine is growing and my capacity to take more risks, and ask more questions is developing me as a teacher and as a leader. I appreciate that CAT values encouraging their employees to do hard things and that it is a safe environment for employees to take appropriate risks.

Integration

So picture this you’re driving your car down the highway and all of a sudden the car in front of you starts to break. You hit your breaks and your breaks do not react quickly enough to cause you to slow down, therefore you hit the person in front of you. (Just to clarify; No one is injured in the creation of this example…) Now imagine, the same scenario taking place you come to a quick stop and the reaction time is accurate and it allows you to avoid any conflict with the surrounding vehicles. What causes that to happen? Did you know that someone spends time assessing what would be best suited for the operator? It’s truthfully why we all have preferences about the cars we drive, the way it feels when we turn the wheel how quickly it jerks, or when we accelerate how quickly that acceleration takes place. This all is tuned by an engineer. I thoroughly enjoyed the opportunity to do this on a skid steer machine with two members of Gareth’s team; Christian and Daniel. I learned about the range of variability and how to set the controls to suit my needs. But let’s be honest anything that gets me out in the field I enjoy! I love being hands on and getting to not just talk but do things! This was a great experience. Quick shoutout to CAT for trusting me to operate your machinery and if you happen to notice a torn up patch of grass near Sanford… it was Daniel and Christian.

Retail

CAT is an incredible company. If anyone got to see what I do they would want to buy from CAT and only CAT. The CAT culture, quality, and care for the product is amazing. A lot of questions that arose for me last week were how this awesomeness was being communicated in the retail experience. How do we help customers know that you guys aren’t just building a product, but people and opportunities as well? I hope that Caterpillar won’t be so quiet or shy to share what makes you all so great in the retail setting! If I had a yard, or even just a pile of dirt I could move around I would purchase a machine in a heartbeat just to say I was a CAT customer. So thank you for being who you say you are. For being an authentic brand.

Before I get into my ideas for lessons I want to do my weekly shoutouts to everyone whom I interacted with. If you are not listed here, my apologies. No matter how big or small the interaction I value you sharing your time and energy with me.

Thank you to Alex, Sherie, Jason, Doug, Courtney, Ashley, George, Angie, Emma, Christian, Kayla, Gareth, George, Wanda, David, Mary, Patrick, Daniel, Korby, Clay, Molly, Jeremy, Doug, Randy, Brandi, Chris, John, Jesse, Mark, Bill, Marvin, Todd, Jason, Rick, Daniel, Chris, Jason, Lexi, Jennifer

Ideas for Implementation

#Improved Idea 1 (Assembly)

Last week I talked about planning and designing a lesson around Assembly. This week I learned how I could improve my Assembly Idea. When meeting with Jason Sage, HR for BCP (Building Construction Parts), he recommended that I ensure that standard work is part of the lesson/unit as well as simulated work environments. I hope to read more on simulated work environments to incorporate this into my plans.

#Idea 2 (No change)

#Idea 3 (Creating a Business model)

Another interesting idea came from my meeting with Lexi Rudolph who works in Communication and increases programs for community for CAT was to help students connect with companies and come up with a business plan or strategy. Students could consider how they could improve a companies marketing, what would their design/logo look like, how would they go about creating a strategy to improve profit for a local company.

Business Plans could also mean students having an opportunity to partner with a local organization to submit a press release, media alert, and what it would look like to make to maintain positive relationships with customers.

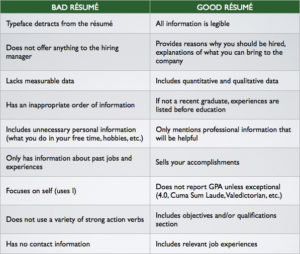

Idea 4 (Resumes/Strength Finders)

I would like to expose students to writing resumes. Below I have found some criteria for creating a quality resume. I would be interested on gaining more feedback here. A tool that I currently use for building resumes is canva.com, but you have any other recommendations please reach out to me on tools I could use with my students.

In addition, I am interested in helping students figure out what there strengths are to provide some direction towards potential careers. Some strength finders I am currently aware of are:

-Enneagram

-Myers Brigg

-High 5 Test

Again, any recommendations are welcome here!

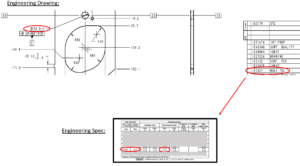

Idea 5 (Engineering Drawings)

Thank you to Angie from Gareth’s team for providing this resource to me. I hope to create some connections between engineering drawings and geometry as well as including this in the assembly process. What should things look like to ensure quality. How can we create specs so that it is consistent across all machines/components.

Until next time,

Ms. A