Gemba is a Japanese term meaning “the real place.” Commonly used in Japan, the police could refer to a crime scene as gemba, and TV reporters often refer to themselves as reporting live from gemba.

Gemba is a Japanese term meaning “the real place.” Commonly used in Japan, the police could refer to a crime scene as gemba, and TV reporters often refer to themselves as reporting live from gemba.

In Kaizen and LEAN manufacturing practices, however, gemba refers to “the place where value is created”. The most common use of the term is in manufacturing, where the gemba is the factory floor. Beyond this, gemba can really be any “site”, such as a building site in construction, the sales floor in retail, somewhere the service provider interacts directly with the customer, or our classrooms full of students, where the value is created.

At the GE Aviation Rotating Parts facility, the leadership teams made up of production supervisors, process engineers, quality engineers, and plant-wide supervisors engage in a daily gemba walk.

At the GE Aviation Rotating Parts facility, the leadership teams made up of production supervisors, process engineers, quality engineers, and plant-wide supervisors engage in a daily gemba walk.

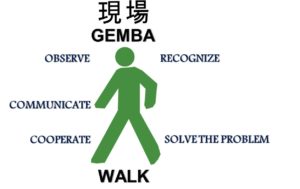

In a lean manufacturing environment like the Rotating Parts plant, the whole point of gemba is that problems in a process or production line operation are often easily visible, and the best improvements come from going to ‘the real place’, where leaders can see the state of the process for themselves. In Japanese manufacturing culture, they use gemba to “Go see, ask why, show respect”

Over the course of a Gemba Walk, production supervisors, process engineers, quality engineers, and plant-wide supervisors are expected to simply observe and understand operation or process. As part of the Kaizen methodology, it is also supposed to encourage greater communication, transparency, and trust between the machine operators and leadership, all part of building a teaming culture. For this reason, it is not appropriate to use a Gemba walk to point out employee flaws or enforce policy, the purpose is to inspect and understand the operation or process.

Over the course of a Gemba Walk, production supervisors, process engineers, quality engineers, and plant-wide supervisors are expected to simply observe and understand operation or process. As part of the Kaizen methodology, it is also supposed to encourage greater communication, transparency, and trust between the machine operators and leadership, all part of building a teaming culture. For this reason, it is not appropriate to use a Gemba walk to point out employee flaws or enforce policy, the purpose is to inspect and understand the operation or process.

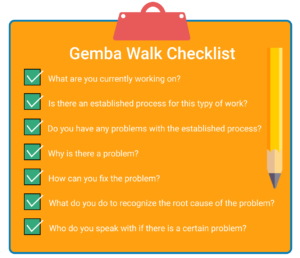

The main objective of a Gemba walk is to explore the manufacturing process in detail and locate its problematic parts through active communication. Kaizen practices encourage a good leader to listen rather than talk. Before making the walk of the rotating parts manufacturing floor, the leadership team make a plan and follow a series of steps. The plan depends on the goals and objectives of the day.

The goal or objective for the day may be productivity, cost efficiency, safety, or quality. In order to be as precise as possible, the teams prepare a list of questions they are going to focus on. The operators that will be observed are prepared for what is going to happen. All team members need to have a clear understanding that the Gemba walk is a common process where the final destination is continuous improvement. The leadership team wants the operators to feel comfortable and willing to collaborate.

The goal or objective for the day may be productivity, cost efficiency, safety, or quality. In order to be as precise as possible, the teams prepare a list of questions they are going to focus on. The operators that will be observed are prepared for what is going to happen. All team members need to have a clear understanding that the Gemba walk is a common process where the final destination is continuous improvement. The leadership team wants the operators to feel comfortable and willing to collaborate.

The leadership team writes down everything that grabs their attention or may record it with a smartphone. In some cases, leadership might be tempted to offer a solution immediately, but according to Kaizen, this would be wrong. A better process will leave the analysis for later. As we discussed yesterday when reviewing quality analysis, observations will be much more precise after you have all the facts available. In addition, the reflection can offer you opportunities to use some of the problem-solving tools we discussed such as DMAIC or an A3 process. As we have mentioned these are much better than following an instant gut feeling.

At the end of the gemba walk, it is very important to share with the operators what was learned or seen. Otherwise, the operators will only have the feeling of being watched or evaluated. If the team is going to take actions after the walk, they ask for input from and inform the operators about the upcoming changes and why they are necessary. It is important to show the operators they are an important part of the process and have a role to play in continuous improvement.

So, what role does a gemba walk have in a middle school? When I think about the PBL process it seems that a structured gemba walk which includes the instructor, and a member from each group so that they can be aware of how the other groups are doing, what problems are being encountered, and what resources are needed would be an excellent addition to improve the process.

When I think about how the evaluation process roles out in our school, it makes me wonder if a daily gemba walk would be a useful exercise. The walk would have a different theme each day, maybe student behavior on Monday, technology use on Tuesday, Safety on Wednesday, PBIS on Thursday, and MTSS on Friday, all at different times of day to ensure that different classes and combinations of students are seen. The walk would not be an evaluation, but just fact-finding, and opportunity for the administration to interact with staff and students. After the walk, they could do some analysis and post thoughts and findings to a shared faculty resource page for discussion and feedback. I am just brainstorming, but after watching a gemba walk in this very complicated manufacturing environment it seems like a logical process for our school.

When I think about how the evaluation process roles out in our school, it makes me wonder if a daily gemba walk would be a useful exercise. The walk would have a different theme each day, maybe student behavior on Monday, technology use on Tuesday, Safety on Wednesday, PBIS on Thursday, and MTSS on Friday, all at different times of day to ensure that different classes and combinations of students are seen. The walk would not be an evaluation, but just fact-finding, and opportunity for the administration to interact with staff and students. After the walk, they could do some analysis and post thoughts and findings to a shared faculty resource page for discussion and feedback. I am just brainstorming, but after watching a gemba walk in this very complicated manufacturing environment it seems like a logical process for our school.