GE aviation has incorporated many corporate-wide initiatives to foster the idea of constant incremental improvement. Many of these initiatives are based on the Toyota production system developed in the mid-1950s.

Kaizen is one of the core principles of The Toyota Production System, a quest for continuous improvement and a single word that sums up Toyota’s ‘Always a Better Way’ slogan.

Kaizen, which means continuous improvement in english, is a philosophy that helps to ensure maximum quality, the elimination of waste, and improvements in efficiency, both in terms of equipment and work procedures. Kaizen improvements in standardized work help maximize productivity across the individual shop, and the organization. Standardized work involves following procedures consistently and therefore employees can identify the problems promptly.

Within the Toyota Production System, Kaizen empowers individual members of a team or cell to identify areas for improvement and suggest practical solutions. The focused activity surrounding this solution is often referred to as a kaizen blitz, while it is the responsibility of each member to adopt the improved standardized procedure and eliminate waste from within the team or cell.

Kaizen begins in the early designs of a production line and continues through its lifetime of use by a process of consensus known as Nemawashi. Kaizen can be incorporated in the manufacturing facility through Flow kaizen and through Process kaizen.

Flow kaizen is oriented towards the flow of materials and information, and is often identified with the reorganization of an entire production area, even a company. Process Kaizen means the improvement of individual workstations or manufacturing cells. Therefore, improving the way production workers do their job is a part of a process kaizen. The use of the kaizen model for continuous improvement demands that both flow and process kaizens are used, although process kaizens are used more often to focus workers on continuous small improvements.

Yesterday I was able to shadow three members of the Kaizen promotion team at the GE Aviation Rotating Parts facility. In the morning I shadowed Rick, who leads the team and has been at this facility for about a year. Rick came here after many years working at the Baxter production facility in North Cove, the leading IV bag production facility in North America. He was a leader in implementing LEAN Manufacturing and Kaizen principles at that plant. In fact, that plant won two national awards during his tenure due to the implementation of these principles.

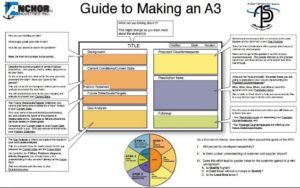

Rick shared some very specific tools used in the Kaizen process, such as the A3  form. The A3 looks at an operational change initiative across nine different areas of documentation. The purpose of the form is to create a record of a change initiative and to ensure that the entire team understands the purpose and scope of the operational change. The nine areas include 1. Reasons for the action – a background statement supplemented with data and objective criteria. 2. Initial state – a description of the current state of the issue referencing specific metrics. 3. Target State – Where do we want the process to improve, again using specific metrics. 4. Gap Analysis – What needs to change to get to the target state. 5. Solution Approach – how we make changes, including a specific list of potential solutions. 6. Rapid Experiments – A list of first pass fast implementation experiments and an analysis of results. 7. Completion plan – Due dates for changes to be implemented. 8. Confirmed State – An analysis of the efficacy of the changes, in theory, it should match number 3 Target State. 9. Insights – What are the fundamental lessons of the event and the improvement cycle. Rick and I discussed how the form can be used, or on occasion misused. Sometimes a process change will lead to a loss in quality, and he made it clear that would lead to backmapping and figuring out a different solution.

form. The A3 looks at an operational change initiative across nine different areas of documentation. The purpose of the form is to create a record of a change initiative and to ensure that the entire team understands the purpose and scope of the operational change. The nine areas include 1. Reasons for the action – a background statement supplemented with data and objective criteria. 2. Initial state – a description of the current state of the issue referencing specific metrics. 3. Target State – Where do we want the process to improve, again using specific metrics. 4. Gap Analysis – What needs to change to get to the target state. 5. Solution Approach – how we make changes, including a specific list of potential solutions. 6. Rapid Experiments – A list of first pass fast implementation experiments and an analysis of results. 7. Completion plan – Due dates for changes to be implemented. 8. Confirmed State – An analysis of the efficacy of the changes, in theory, it should match number 3 Target State. 9. Insights – What are the fundamental lessons of the event and the improvement cycle. Rick and I discussed how the form can be used, or on occasion misused. Sometimes a process change will lead to a loss in quality, and he made it clear that would lead to backmapping and figuring out a different solution.

It is clear that collecting data, hypothesis testing, and quick experimentation are all steps to move towards process improvement. When I think about our school improvement process and the tools we use, particularly Indistar, I think we can learn a lot from Kaizen and the Toyota Production System that can be applied directly in our classrooms. As I look over the form I definitely see some application in my classroom and school as we look to improve some processes in the building. As I step back from the experience I am having at GE Aviation it is important that I figure out the relationships between process and quality improvement, how I can use these tools, and how I can make these lessons real for my students.

The HR manager at Coats also shared this with me! I plan to implement it often in my classroom. It is interesting that both companies use this strategy. I look forward to speaking with you about your thoughts and ideas.