(Note: All last names omitted to protect privacy)

Day 2 at GE Aviation has allowed me to meet with some of the production supervisors, process engineers, quality engineers, and actually get out on the rotating parts plant floor to see parts being manufactured. The title of this entry is from the GE Aviation Vision Statement hanging near the door to manufacturing floor “To Solidify Western North Carolina’s footprint in advanced manufacturing, reaching every corner of the world for generations to come.” I think this vision statement clarifies what this fellowship is all about, impacting our region, and by extension, our world, for generations to come by addressing the needs of our students and the advanced manufacturing leaders in our region.

My day started with my inclusion in a Plant Control Center meeting. Each manufacturing cell is represented by the production supervisor for the cell. This meeting was focused and fast. Everyone was standing, including the meeting facilitator, the facility Lead Process Engineer. Joe facilitated the meeting from an excel spreadsheet which had a series of action items related to specific parts and their progress. The cell production supervisors quickly answered questions and worked through issues related to quality assurance standards and the process flow. As specific products and action items were dealt with production managers quietly left the meeting with no disruption. The group tackled 11 parts and related action items in 15 minutes as Joe updated the spreadsheet with notes or additional action items.

After the meeting, I was able to tag along with one of the production supervisors,  Steve, to ask questions and observe his manufacturing cell during production. I asked Steve what qualities he values most in his production employees. Steve made it clear that a good employee is going to have a technical background, blueprint reading, skills with tools, etc, but the skills he values most are what we traditionally call “soft skills”. He explained that production staff needs to be disciplined, have integrity, and be good listeners. In addition, they need to accept criticism as a path to improvement, not take things personally, and they need to be team oriented and willing to work together to gain efficiency, not to just accept doing things because that is the way they have always been done. As an example, Steve allowed me to watch a young employee, Justin, who was working as an apprentice learning how to run a four spindle machine operation. Justin was working here through his senior year at Pisgah High School in Canton as part of his high school curriculum, and he had recently graduated from Pisgah just two weeks ago. His Metals teacher, Chip Singleton, had actually worked in this plant many years ago. Multiple students from Pisgah had come to this GE facility and found success as an extension of the metals program through an apprenticeship program started by the school. The apprentice program started 3 years ago and the plant now has 12 Pisgah graduates. This is a really excellent concept, treating the students who sign on as apprentices just like the students who sign athletic scholarships. This is one way that we can show how we value advanced manufacturing and the impact it has on our local economy.

Steve, to ask questions and observe his manufacturing cell during production. I asked Steve what qualities he values most in his production employees. Steve made it clear that a good employee is going to have a technical background, blueprint reading, skills with tools, etc, but the skills he values most are what we traditionally call “soft skills”. He explained that production staff needs to be disciplined, have integrity, and be good listeners. In addition, they need to accept criticism as a path to improvement, not take things personally, and they need to be team oriented and willing to work together to gain efficiency, not to just accept doing things because that is the way they have always been done. As an example, Steve allowed me to watch a young employee, Justin, who was working as an apprentice learning how to run a four spindle machine operation. Justin was working here through his senior year at Pisgah High School in Canton as part of his high school curriculum, and he had recently graduated from Pisgah just two weeks ago. His Metals teacher, Chip Singleton, had actually worked in this plant many years ago. Multiple students from Pisgah had come to this GE facility and found success as an extension of the metals program through an apprenticeship program started by the school. The apprentice program started 3 years ago and the plant now has 12 Pisgah graduates. This is a really excellent concept, treating the students who sign on as apprentices just like the students who sign athletic scholarships. This is one way that we can show how we value advanced manufacturing and the impact it has on our local economy.

The regular employee who was mentoring this apprentice, Jimmy, explained that this station had formerly been run by 4 employees, one at each machine. But through improvements in efficiency, design and digital technology, the four different machines could now be managed by one employee. Jimmy had been part of the redesign allowing for these changes. Even though it means fewer employees, it raises efficiency and the overall profits of the plant, which in turn has created new jobs and opportunities throughout the plant.

Watching Justin work it was obvious he was very detail oriented, as multiple parts needed to be adjusted and aligned as part of the milling process. He was meticulous, checking his measurements twice with multiple instruments before resetting the milling process. Mistakes could lead to errors that cost thousands of dollars, not to mention a breach in quality could cost lives. Later in the day, I was able to speak with Cody, one of the original participants in the apprenticeship program. When I asked Cody what he liked most about this work he said: “I really like the problem solving, figuring out how to make things work so that our parts are always top quality”. He went on to say that the work can be stressful, but the organization and process management approach allows for him to “slow down and keep his head” when things start to back up on the floor.

Watching Justin work it was obvious he was very detail oriented, as multiple parts needed to be adjusted and aligned as part of the milling process. He was meticulous, checking his measurements twice with multiple instruments before resetting the milling process. Mistakes could lead to errors that cost thousands of dollars, not to mention a breach in quality could cost lives. Later in the day, I was able to speak with Cody, one of the original participants in the apprenticeship program. When I asked Cody what he liked most about this work he said: “I really like the problem solving, figuring out how to make things work so that our parts are always top quality”. He went on to say that the work can be stressful, but the organization and process management approach allows for him to “slow down and keep his head” when things start to back up on the floor.

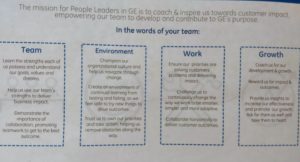

Later in the morning, I was able to Shadow Angela, another production  supervisor. Angela shared that machinists are classified as skilled, highly skilled, and advanced. the Advanced Machinists have an Employee Performance Evaluation which provides for observation across 10 categories. You might suspect that this evaluation would be primarily focused on technical aspects, and there are many like “Ability to run multiple machines/processes in and outside area” and “Demonstrates ability to set up parts, modify fixtures, and partner with process engineers”. But in reality, it focuses on a variety of soft skills that help employees bring more value to the shop floor. For example, Standard 1 “Willing to train new and existing employees, shows an interest in their success” and Standard 5 “consistently exhibits desired traits regarding behavior including integrity, honesty, respect, positive attitude, teamwork, dependability, etc”. Standard 6 states “Consistently hits standard and helps others improve performance”, Standard 7 “Owns up to mistakes, brings issues forward, and addresses issues immediately” and “proposes corrective actions and acts to prevent recurring issues”. In standard 8 “recognizes where others need help and offers to jump in” and Standard 9 “Champions ideas for improvements and encourages others to do so as well” and Standard 10 “Embraces teaming”.

supervisor. Angela shared that machinists are classified as skilled, highly skilled, and advanced. the Advanced Machinists have an Employee Performance Evaluation which provides for observation across 10 categories. You might suspect that this evaluation would be primarily focused on technical aspects, and there are many like “Ability to run multiple machines/processes in and outside area” and “Demonstrates ability to set up parts, modify fixtures, and partner with process engineers”. But in reality, it focuses on a variety of soft skills that help employees bring more value to the shop floor. For example, Standard 1 “Willing to train new and existing employees, shows an interest in their success” and Standard 5 “consistently exhibits desired traits regarding behavior including integrity, honesty, respect, positive attitude, teamwork, dependability, etc”. Standard 6 states “Consistently hits standard and helps others improve performance”, Standard 7 “Owns up to mistakes, brings issues forward, and addresses issues immediately” and “proposes corrective actions and acts to prevent recurring issues”. In standard 8 “recognizes where others need help and offers to jump in” and Standard 9 “Champions ideas for improvements and encourages others to do so as well” and Standard 10 “Embraces teaming”.

While I may not be able to teach the very specific technical skills needed on the shop floor (beyond mastering a dial caliper), I and my middle school colleagues can certainly help build the habits that will lead to our students bringing these soft skills and traits into a facility like the GE Aviation rotating parts plant.