A Day in the Life: Exploring Biomanufacturing Careers

| Author: | Lori Stroud |

| Level: | Middle School |

| Content Area: | Science, Biotechnology, Physics |

| Author: | Lori Stroud |

| Level: | Middle School |

| Content Area: | Science, Biotechnology, Physics |

|

Mini Bioreactor Equipment and materials for students |

|

| Equipment and notes | Quantity per group (recommend 2-4) |

| □ 250 mL Flask (shake) | 1 |

| □ 1000 mL Flask | 1 |

| □ #7 One Hole Stopper | 1 |

| □ Tubing (6 inches of polypropylene that is ¼” outside diameter and 20 inches of silicone that is 3/16” inside diameter) | 1 |

| □ 100 mL Graduated Cylinder (polypropylene) | 1 |

| □ 1000 mL Beaker (polypropylene) | 1 |

| □ Timer (optional) | 1 |

| □ Thermometer (if using hot plate to heat water) | 1 |

| □ Hot plate (optional) | 1 |

| □ Hot mitts (if using hot plate) | 1 |

| □ Baker’s yeast ~Saccharomyces cerevisiae (Red Star® was used when preparing this activity) | 2.1 g |

| □ Sugar (Sugar in the Raw™ was used when preparing this activity) | Assign amount using variables chart |

| □ Soy Flour | Assign amount using variables chart |

| □ Lab tape | 1 roll |

| □ Weigh boats | 3 |

| □ Water | 700 mL in a 1000 mL flask |

|

Mini Bioreactor Equipment and materials for instructor preparation |

|

| Equipment and notes | Quantity |

| □ Microwave (central access for students to use to warm water if not using hot plates) | 1 |

| □ scales and or balances | 1-3 |

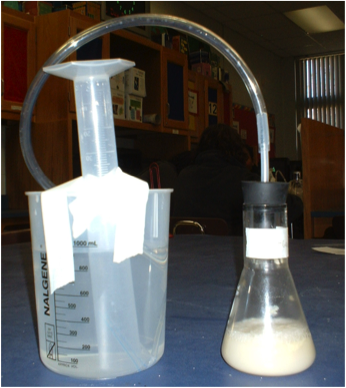

In addition, a curved piece of polypropylene tubing needs to be attached to the other end of the silicone tubing. A large bendable straw can be used for this, or the remaining 3 inch piece of polypropylene tubing can be heated and bent. This piece of tubing will be inserted into the graduated cylinder during the experiment.

|

Group |

Carbon (Sugar) |

Nitrogen (Flour) |

| 1 | Neutral (1.6g) | Neutral (1 g) |

| 2 | -100% (0 g) | -100% (0 g) |

| 3 | Neutral (1.6 g) | -100% (0 g) |

| 4 | -100% (0 g) | Neutral (1 g) |

| 5 | + 50 % (2.4 g) | +50% (1.5g) |

| 6 | + 50 % (2.4 g) | -50% (.5g) |

| 7 | -50% (.8 g) | -50% (.5g) |

| 8 | -50% (.8 g) | +50% (1.5g) |

| 9 | Neutral (1.6g) | +50% (1.5g) |

| 10 | +50% (1.5g) | -50% (.5g) |

| 11 | + 50 % (2.4 g) | Neutral (1 g) |

| 12 | -50% (.8 g) | Neutral (1 g) |

To gain greater data, these percentages can be altered even more. If a teacher has multiple classes, the data can be shared from class to class. The teacher will need to assign the appropriate amounts of sugar and flour to the groups and direct them to record those amounts on their batch record prior to beginning the lab.